Abstract

Teff is a staple of Ethiopian culture and national identity and is very nutrient-dense. Ethiopia and its farmers now have more economic opportunities as a result. The process of planting involves putting seeds in the ground for optimal germination. It is among the most significant cultural customs related to the production of crops. At present it has little development in teff row seeder in Ethiopia. However, their field evaluations showed that, none of the developed planters has been functioned effectively, in way of the desired functional requirement, especially in all soil types as well as weather conditions of the country. So many research institutes and private sectors have been developed different types of teff row planting device which seed from single to many rows, animal drawn and operated manually. This work focused on the creation and performance evaluation of an inexpensive self-propelled five rows air seeder teff row planter in order to overcome the need for human labor for sowing, which leads to delayed operation, low yield, and high production costs. The developed machine consists of different major component parts like seed and fertilizer hoppers, driving wheel, air diffuser, controlling mechanism, seed and fertilizer delivery chute and the like. The planting machine's effective field capacity, theoretical field capacity, and field efficiency were determined to be 0.25 ha/hr, 0.31 ha/hr, and 0.81 ha/hr, respectively, during the performance evaluation. The largest plant population was observed replication 5 and the smallest observation was recorded at replication 3 which was 141.3 and 103.5 respectively.

|

Published in

|

Industrial Engineering (Volume 9, Issue 2)

|

|

DOI

|

10.11648/j.ie.20250902.13

|

|

Page(s)

|

48-59 |

|

Creative Commons

|

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited.

|

|

Copyright

|

Copyright © The Author(s), 2025. Published by Science Publishing Group

|

Keywords

Planter, Traction, Performance, Design, Evaluation, Self Propelled, Field Capacity

1. Introduction

One of the most crucial crops for Ethiopia's farm revenue, food security, and nutrition is teff, or Eragrostis tef, the country's oldest indigenous staple food. Teff is a staple of Ethiopian culture and national identity and is very nutrient-dense. Teff is becoming more and more well-known worldwide as one of the newest superfoods of the twenty-first century, much like the ancient Andean grain quinoa

| [2] | Abraham R, Dechassa N, Assefa K. Evaluation of seed rates and sowing methods on growth, yield and yield attributes of tef [Eragrostis tef (Zucc.) Trotter] in Ada District, East Shewa, Ethiopia. Am Eur J Agric Environ Sci. 2018; 18(1): 34–49. |

[2]

. Ethiopia and its farmers now have more economic opportunities as a result. Additionally, it poses a threat to Ethiopia's food security and the associated problem of lowering hunger, poverty, and chronic malnutrition.

The process of planting involves putting seeds in the ground for optimal germination. It is among the most significant cultural customs related to the production of crops. An exercise that should produce fast and consistently emerging plant stands at the appropriate density. Proper seeding results in the right number of seed per unit area, the right depth of seed in the soil, and the right distance between plants and rows. For effective harvesting in a mechanized setting, this is a crucial component. The type of crop and the agroclimatic conditions required to obtain the best yield determine the seed-to-seed spacing

| [15] | Kyada, A. R and Patel, D. B. 2014. Design and Development of a Manually Operated Seed Planter. 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014) December 12th–14th, 2014, IIT Guwahati, Assam, India. |

| [18] | Mysara, A. M, Abdalla, N. O. K., Abbas, E. R. and Husam, A. B. Y. 2017. Performance evaluation of two planters make as affected by forward speeds. Journal of Agricultural Science and Practice. 2, 16 – 22. |

[15, 18]

and

| [20] | Soyoye, B. O., Ademosun, O. C. and Agbetoye, L. A. S. 2018. Determination of some physical and mechanical properties of soybean and maize in relation to planter design. Agricultural Engineering International: CIGR Journal, 20(1), 81–89. |

[20]

.

By reducing competition amongst plants for resources like light, water, and nutrients, uniform seed dispersal in the soil promotes better germination and emergence and higher yield. Numerous elements, including the seed metering system, seed delivery tube, furrow opening design, seed physical characteristics, and soil conditions, influence how seeds are distributed in soil

| [13] | Karayel, D., and A. Özmerzi. "Evaluation of three depth-control components on seed placement accuracy and emergence for a precision planter." Applied Engineering in Agriculture 24.3 (2008): 271-276. |

[13]

.

Sowing seeds is a lot of work, particularly if done by hand. Therefore, in order to maximize productivity and ensure efficient operation, the process must be mechanized. One of the most crucial aspects of any agricultural operation is timeliness, which can only be accomplished with the use of the right machine

| [15] | Kyada, A. R and Patel, D. B. 2014. Design and Development of a Manually Operated Seed Planter. 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014) December 12th–14th, 2014, IIT Guwahati, Assam, India. |

[15]

. In the majority of Ethiopian farms, seeding is often done by hand. A highly slow, tiresome, costly, and time-consuming process that frequently leads to inefficient seed distribution and spacing, farm labor, and consequently low yield and productivity. One of the most notable developments in global agriculture over the past ten years has been the use of machinery for agricultural tasks

| [1] | Abdalla, A. N. O. 2007. Comparison of two row planting machine performance as affected by forward speed under two soil condition. M.SC. Thesis University of Khartoum. |

[1]

.

At present it has little development in teff row seeder in Ethiopia. However, their field evaluations showed that, none of the developed planters has been functioned effectively, in way of the desired functional requirement, especially in all soil types as well as weather conditions of the country.

So many research institutes and private sectors have been developed different types of teff row planting device which seed from single to many rows, animal drawn and operated manually. The power transmission system of the seeder, however, uses a number of driving methods, ranging from the drive wheel to the counter shaft via sprockets and chains. It's a complex system that goes via a second and third set of shafts, chains, and sprockets before driving the seed measuring plate and then through bevel gears. In instance, training draft animals to operate an animal-drawn planter to maintain furrow spacing the most difficult aspect of the previously created planters would require strong technical skills for both operation and maintenance.

The development and adoption of indigenous planting equipment is necessary to overcome the reliance on human labor for sowing, which leads to delayed operations, low productivity, and high production costs. Researchers have produced numerous groundbreaking advancements in the field of planter development for a variety of crops. Even though the mechanization of the seeding process has attracted a lot of attention lately, it is still necessary to transform seed planting operations by creating high-quality machines that perform well, taking into account the technicality and financial capabilities of local farmers in general and teff crops in particular, which are only left out of international crops in terms of mechanization. Therefore, the development and performance assessment of a low-cost, self-propelled, five-row air-assisted teff row planter were the main objectives of this project.

2. Materials and Methods

2.1. Experimental Site

The Bako Agricultural Engineering Research Center (BAERC), situated in West Shewa, is where the machine was manufactured. It is located in a sub-humid agro-ecological zone between latitudes 9°04ꞌ 45ꞌꞌ to 9°07ꞌ 15ꞌꞌ N latitudes and 37°02ꞌ to 37°07ꞌ E longitude in sub-humid agro-ecological zone. The average air temperature is 13.20 degrees at the minimum and 27.90 degrees at the maximum. The machine's testing and performance assessment were carried out in Ethiopia's Oromia National Regional State's Ambo District, West Shewa Zone.

2.2. Design Considerations

The following design elements were deemed significant: cost, function, dependability, maintenance, and safety. Specifications like higher throughput, continuous operation, efficiency, and the availability of manufacturing materials and spare parts were taken into account when designing a planting machine. The goal of this study was to create a machine that was affordable, lightweight, sturdy, and easy enough for peasant farmers to use. This was accomplished by taking into account a number of elements. Seed combinations, soil characteristics, building material availability and strength, machine safety and ergonomics, ease of use, power requirements, maintainability, and machine component efficiency are a few examples. The viability of seeds should not be impacted in any manner during planting by any other method in order to preserve their quality.

2.3. Materials

Raw materials used for manufacturing of the machine were angle iron, mild steel sheet, water pipe, solid shaft, iron rods and spare parts like; pulley, chain and sprockets, bearing, bolts and nuts, and consumables electrode and Rubin engine.

2.4. Description of the Planting Machine

The planter consists of one seed and one fertilizer hopper. The seed hopper was made from plastic material to minimize the cost and weight of the machine. It was connected at the top of seed delivery chute and the air diffusion chamber and provided with hole to deliver the seed of diffusion. The spring loaded stopper was provided at the bottom tip end of the hopper to control free flow of the teff seed during turn at the head of the farm land. Seeds were metered by gravity from the hopper. The frame was constructed from 40 mm by 40 mm angle iron that was 4 mm thick in order to support an engine and a power transmission element. The planter handle was built using a water pipe while taking ergonomic considerations into account. Angle iron 40 mm by 40 mm by 4 mm served as the engine seat that was slit for belt connection to the prime mover. The fan or blower made of mild steel sheet of 1.5 mm thick to create air assisting the delivery of the seed through the tube. should not be affected in any way during planting by any other means by the machine or any of its part, especially the seed metering device. Air diffusion chamber was connected at the end of the blower to distribute air to each deliver tube assisted by partition made in the chamber. Pulley and belt were used to transmit power from engine to blower and ground wheels. Plastic hose was used to deliver the metered seed to the prepared seed bed.

Figure 1. Description of machine component parts.

2.5. Determination of Physical and Mechanical Properties of Teff

Size, shape, density, repose angle, coefficient friction, tensile and compressive strengths, and other mechanical and physical characteristics of grains were measured or calculated by

| [12] | Gumble, L. O., & Maina, C. (1990). Friction coefficient of cereal seeds on various surfaces. Agricultural Mechanization in Asia, Africa and Latin America, 21(4), 61–64. |

[12]

.

| [3] | Abduljelil, M., 2010. Investigation into tef grain, straw and chaff mixture separation and cleaning. Unpublished Master’s. Thesis). Adama University, Adama, Ethiopia. |

[3]

measured and/or computed the density of tef grains, the coefficient of friction on various materials, the arithmetic and geometric mean diameters, the equivalent diameter, the coefficient of friction on various materials, and the average diameter (based on major and minor axis diameters). Within the moisture range of 11.94 to 27.10 percent (wb), the coefficient of static friction tends to increase from 0.36 to 0.50, respectively. Since teff crop was planted in very humid air condition the repose angle of the seed delivering chute was made to be more than 0.5

| [22] | Zewdu. and Solomo. 2007. Moisture dependant physical properties of Teff seed, bio-systems engineering. 96(1): 59-63. |

[22]

.

2.6. Aerodynamic Properties of Teff Grain

According to

| [17] | Mohsenin, N. N., Jindal, V. K. and Manor, A. N., 1978. Mechanics of impact of a falling fruit on a cushioned surface. Transactions of the ASAE, 21(3), pp. 594-0600. |

[17]

, understanding the aerodynamic properties of each particle involved is necessary to separate a product from its associated but unwanted components, such as straw and chaff, in an air stream. Therefore, in pneumatic conveying and separation, the terminal velocity (Vt) is a crucial aerodynamic property of materials.

| [3] | Abduljelil, M., 2010. Investigation into tef grain, straw and chaff mixture separation and cleaning. Unpublished Master’s. Thesis). Adama University, Adama, Ethiopia. |

[3]

discovered that when the moisture content increased from 11.94% to 27.00% (wb), the terminal velocity of tef grain increased from 3.24 m/s to 4.04 m/s. In order to determine the blower speed, which was modified based on the pulley ratio, the terminal velocity of the teff grain 3.24 m/s was used

| [22] | Zewdu. and Solomo. 2007. Moisture dependant physical properties of Teff seed, bio-systems engineering. 96(1): 59-63. |

[22]

.

2.7. Row Spacing

The distance between the center of one seed tube exit and the center of the subsequent outlet is known as row spacing. Sunlight, weed competition, and nutrient placement all affect row spacing. The main factors influencing seeding rate are available moisture and weed competition

| [8] | Debelo, Aberra, 1992. Germination, yield, and yield components of tef (Eragrostis tef (Zucc) Trotter) as affected by environment, tillage and weed control practices. Oklahoma State University. |

[8]

. Row spacing and seeding rates are therefore occasionally altered based on soil fertility, season, and variety. According to

| [9] | Ethiopian agricultural transformation Agency (ATA) in 2013 report. |

[9]

, the critical dimension is unaffected by any variation factors, and the row spacing dimension is 20 cm between rows. Another study by

| [14] | Kassaye, Wubante Negash Ahadu Menzir Mulatu. "Effect of Row Spacing on Yield and Yield Components of Teff [Eragrostis tef (Zucc.) Trotter] Varieties in Gonji Kolela District, North Western Ethiopia". |

[14]

found that 20 cm and 25 cm inter row spacing produced the highest grain yields. In order to construct the furrow opener and seed distribution tube, a 20 cm inter row gap was used.

2.8. Depth of Seed Placement

The importance of sowing depth as a crucial component of grain management techniques was covered. Compared to seeds sown shallow (2–3 cm), drilling 6 cm into damp soil gives the grains a better chance of surviving a brief drought and increasing grain output due to improved establishment

| [6] | Behailu Getu. 2014. Assessment of Factors Affecting Farmers’ Adoption level of Row Planting Technology and Yield Improvement on the Production of Eragrostis Teff [ZUCC.], Addis Ababa University. |

[6]

. The crop area must be extremely leveled to reach this limit, even if sowing depth is crucial, but this is not feasible. Cattle, sheep, goats, donkeys, and occasionally people are used to compact the soil in Teff fields throughout the majority of the nation. To make the seedbed hard, keep the soil surface from drying up too soon, which would desiccate the seeds, and improve germination, teff requires a moderate amount of soil compaction. Therefore scraper provision was made for seed delivery chute to scrap place of seed dropping since there is consensuses teff deep planting.

2.9. Seeding Rate

The component that impacts yield is seed rate because uneven seed distribution makes it harder to pull weeds after the plants are mature and increases competition among teff plants for nutrients, light, and water

| [7] | Bekabil fufa, Befkadu Behute. 2011. Rupert Simon, and Tareke Berhe, Strengthening the tef value chain in Ethiopia, Ethiopia agricultural transformation agency. |

[7]

. In the old seed broadcast technique, the rate was high, ranging from 25 to 50 kg/ha

| [9] | Ethiopian agricultural transformation Agency (ATA) in 2013 report. |

[9]

. A researcher's examination reveals that soil fertility and variety affect seed rate. To minimize rivalry between seedlings and enable the best possible branching out of the plants, however, 3-5 kg of seed should be drilled per hectare while maintaining the previously established gap, according to the ATA document and the advice of agriculture experts. It will occasionally vary depending on the season and kind of soil. Since there is a controversy on the seed rate the planting machine was provided with spring loaded controlling mechanism at the top of seed delivery tube.

2.10. Design Computation Teff Planter

CATIA software was used to design the machine's drawing. The strength and stability of the building materials were crucial in order to achieve the necessary standards for effective performance and to create a dependable machine

| [11] | Fadele, O. K. and Aremu, A. K., Effects of Seed Condition, Operation and Design Parameters On Out-Turn Of Moringa Kernel. |

[11]

. Hopper capacity, power need, draft power, solid shafts, a system for measuring seeds and fertilizer, wheel and furrow openers, pulley diameters, belt tension, and length were all taken into consideration throughout the design process.

3. Fabrication of the Planter Components

3.1. Frame

All of the machine's parts are supported by the frame. The primary parts attached on the frame include the engine, blowers, power transmission elements, hopper, and bearings, among others. The components that were to be put on the frame served as the basis for the frame's design. Weight, necessary strength and dependability, and easily accessible material were taken into consideration when choosing the main frame's material. Its 40 mm by 40 mm by 4 mm angle iron construction allowed it to be sturdy enough to support the entire component assembly.

Figure 2. Frame of the planter.

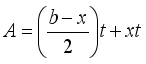

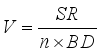

3.2. Seed and Fertilizer Hopper Design

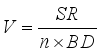

The metering and controlling mechanism were attached to the bottom of the five-liter plastic jar that served as the planter seed hopper. Depending on the necessary seed rate, the spring-loaded regulating mechanism had varying opening ranges. The seed had five holes, each 3 mm in diameter, and was permitted to flow freely by gravity under the controlling mechanism. Using Eq. (

1) blow, the hopper's volume was calculated. Assuming the seed rate per hectare 15 kg and number of refill 3 times, bulk density for kuncho variety to be 1740 kg/m

3, the volume of the seed hopper calculated to be 0.003 m

3. Therefore, 5 liter plastic jar was selected used for seed hopper.

(1)

(1) Where: SR= Seed Rate (kg/ha), BD = Bulk Density of teff grain (kg/m3), n = number of refilling per hectare.

The circular aperture or orifice at the bottom of the hopper was created to safeguard the teff seed's bridging action while planting. Another fertilizer hopper was constructed using 1.5 mm thick sheet metal and has a cylindrical shape. Its volume was determined to be 0.014 m3 by taking the bulk density of DAP, which is 1050 kg/m3, and estimating the weight of the fertilizer, which is 15 kg, in order to reduce the machine's load. Similar to the seed hopper, the fertilizer hopper has an adjustable mechanism for opening and shutting based on the rate of application.

3.3. Handle

The handle is made of a U-shaped, hollow pipe with an internal diameter of 19.02 mm and dimensions of 1000 x 800 x 1000 mm. The handle was attached to the machine's frame with nuts and bolts, and it had a mechanism for opening and closing seeds and fertilizer.

4. Power Transmission Design and Selection

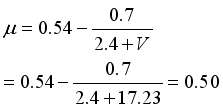

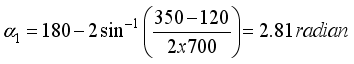

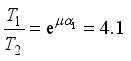

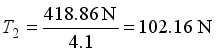

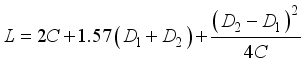

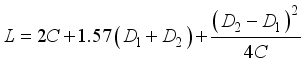

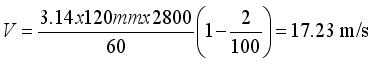

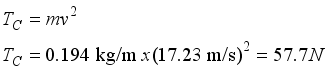

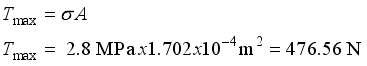

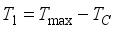

4.1. Estimation of Belt Length

According to

| [16] | Khrmi, R. S & Gupta, J. K (2004), Theory of Machines, Eurasia publishing housing, New Delhi. |

[16]

, the length of belt needed to convey power must be determined using Equations (

2) and (

3). The calculated length of the belt was 2216.79 mm; the nearest length from the catalogue is 2215 mm which V-belt code B 87. Since the engine seat was adjustable the tension tight of the belt was made by moving an engine seat for and backward

| [10] | Eugene, A. A. and Theodore, B. (1986): Standard Handbook for Mechanical Engineering. McGraw Hill Book Company, P. 8-57. |

[10]

.

(2)

(2) The center distance (C) between the two pulleys must be at least twice as large as the larger pulley's diameter.

(3)

(3) where: -

D1 and D2 = diameters of driving and driven pulleys (mm),

C = center distance (mm),

L = belt length (mm)

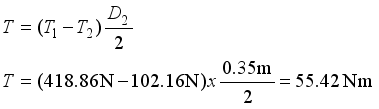

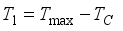

Using the following equations, the tension in the belt's tight side was determined.

(4)

(4) Maximum belt tension,

(5)

(5) The belt's centrifugal tension (Tc) was determined using;

(6)

(6) The belt's mass per unit length,

(7)

(7)  (8)

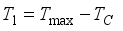

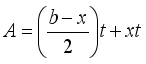

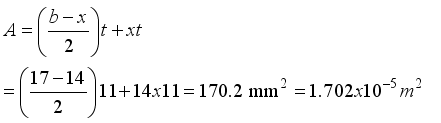

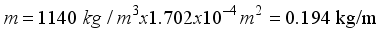

(8) From the perspective of minimal pulley diameter, the choice of belt section was restricted. Belt section B was enough for power transmission from engine to shaft when a minimal smaller pulley diameter of 120 mm was used. Assuming a top width of b = 17 mm, a thickness of t = 11 mm, and a bottom width of 14 mm, the cross-sectional area of the belt was computed. The average of the range, 38˚, was taken as the belt's groove angle.

Since rubber belts are used in the majority of agricultural machinery, their density is 1140 kg/m3.

Equation (

6) was used to determine the belt's velocity as it passed over the follower per second.

Since the active arc of contact is unknown and the belt slips at the smaller pulley first are thought to be 2%, the calculations for a belt drive are often based on the complete arc of contact θ of the smaller pulley (full load) for practical design considerations.

Therefore,

Maximum tension in the belt,

As a result, the belt's tight side tension was computed as follows:

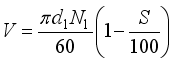

where: - Tc and Tmax represent the centrifugal and maximum tension of the belts (N), A is the belt's cross sectional area (mm2), m is the mass per unit length (kg/m) of the belts, v is the belt's speed (17.23 m/s), b is the belt's top width (17 mm), x is its bottom width (mm), d1 is the driver's diameter (mm), N1 is the driver's speed (2800 rpm), S is the percentage of slip (2%), σ is the maximum permissible stress of the belt (2.8 MPa), t is the belt's thickness (11 mm), and ρ is the density of the Rubber material (1140 kg/m3).

Belt tension ratio was calculated using Equation below.

where: -

= coefficient of friction between belt and pulley;

α1 = angle of wrap for smaller pulley (rad).

V= velocity of belt (m/s)

The following formula was used to calculate the coefficient of friction between the belt and the pulley.

The wrap angle of the engine pulley when the largest drum beater pulley used was determined as below,

Tension at slack side,

The following formula can be used to determine torque on a shaft.

where:- T1 = tight side tension of belt (N), T2 = slack side tension of belt (N) and D2= diameter of the largest driven pulley (m).

4.2. Chain and Sprocket Selection

In order to achieve high traction power and speed reduction, Yamaha motor chain and sprockets were chosen to transfer motion from the first torque converter shaft to the second torque converter and traction wheel. To transfer power from the sprocket to the shaft, the front and rear sprockets were equipped with hub and keyway mechanisms.

4.3. Design of Pulley

Eq. (

9) was used to determine the spinning shaft's pulley and belt velocity ratio.

Where: 𝑁1 is driver speed, 𝐷1 is the driver pulley diameter, 𝑁2 is the shaft speed and 𝐷2 is the shaft pulley diameter. Substituting 𝑁1= 2800 rpm, 𝐷1 = 120 mm, 𝐷1 = 350 mm. Therefore, the speed of the shaft of 960 rpm was used.

4.4. Shaft Design

The American Society of Mechanical Engineering

| [4] | ASME. 1995. Design of Transmission Shafting. American Society of Mechanical Engineering, New York, NY USA. |

[4]

provided the following formula, which should be used to determine the diameter of a solid shaft with little or no axial loading.

(10)

Consequently, the diameter of the first power transmission shaft was calculated to be 19.18 mm using the calculation above. Therefore, based on the expected bearing bore diameter, a shaft size of 25mm was chosen from the standard shaft catalog. The wheel was provided with spoke keep the circular round bar in proper position and to support the upward and down ward forces.

4.5. Traction Wheel Design

To improve traction on dirt, the traction wheel was constructed using 14 mm round bar that was rolled to a diameter of 50 cm and 40 mm by 40 mm by 4 mm angle iron that was 20 cm long. The iron was welded onto the circular round bar. The planter have about three wheels, two of the front wheels used to create traction and the rear one is used to steer and also to support the weight the machine.

4.6. Design of Air Distribution Chamber

The seed metering mechanism was gravity flow, the closing and opening was controlled by spring loaded lever. To ensure equal seed distribution and minimize seed blockage in the seed delivery tube, an air stream was injected into the freely flowing seed at the midpoint of the tube. The air chamber was designed by assuming the terminal velocity of the teff seed, make the required air pressure by sucking air at the intake side to air delivering tube.

Figure 4. Air distribution chamber and impeller.

5. Principle of Operation

The machine will be built with ease of use in mind for every part. A diesel engine will power the machine, and the drive shaft that engages the blower and wheels will be connected to the belt, pulley, chain, and sprockets arrangement. incredibly superficial The scraper or furrow openers will make the openings, and the seed will pass through the bottom hopper hole before being expelled by the delivery hose.

6. Experimental Procedures for Evaluation

To examine the seed discharge rate, consistency of seed spacing, and distribution pattern during operation, a laboratory test was carried out. Bako Agricultural Engineering Research Center (BAERC) conducted the laboratory test. To determine the machine's operating speed, a necessary distance must be written out in the center. The engine was run at a specific fuel acceleration while the seeds were loaded into the hoppers. Three replications of the time it took to travel the distance were used to determine the speed in kilometers per hour, which corresponds to planting speed.

6.1. Machine for Test

Before beginning any testing, the machine's production was finished and operational, with requirements pertaining to materials, construction, range of adjustments, and projected performance under different conditions. In order to prepare them for laboratory and field performance tests, several important pieces were fully manufactured with the required functionality, preset specifications, and dimensions.

6.2. Laboratory Work

(i). Tests of Metering Mechanism

These tests aim to evaluate the metering mechanism's performance, the outcome of which can supply the fundamental information for field performance. The seed was guided down the delivery tube using a gravity flow approach with air blowing as the metering mechanism.

(ii). Forward Traction Test

Forward traction was created by arranging Yamaha chain and sprockets in the way reducing the speed generated from an engine. About two torque converting mechanism were developed to reduce the speed of the machine in order to bring to the speed in pace step of human since the machine guided from behind like power tiller. Due to this high tractive power and high torque was developed at final driving wheel of the machine. The forward traction test was conduct at the center on hard soil and ploughed farm, so that no wheel sleep was investigated during the test run unless rolling lose due to shear force of the soil.

(iii). Seed and Fertilizer Blockage Investigation

Seed and fertilizer metering mechanisms were observed to investigate for any blockage of the openings of the delivery tubes. The blockage of seed and fertilizer were checked at any stage of the operation to determine the seed and fertilizer distribution uniformities.

6.3. Planter Performance Evaluation

In order to ascertain and observe the pattern of seed dispersion along the rows, planting was done. Several quantifiable metrics, including the number of seeds planted or discharged per row, regularity of distribution, effective field capacity, and field efficiency, were calculated using this.

(i). Field Work

Only through field testing can the effective performance of planters be ascertained. Reliable information was gathered about the effects of movement and vibration on seed spacing and application rate, as well as the simplicity of use, maintenance needs, and adjustments needed for different soil and field conditions.

(ii). Determination of Field Capacity and Efficiency

The purpose of the field testing was to ascertain the machine's effective field capacity and field efficiency at a specific vertisoil in the west Shewa Ambo District during the primary teff planting season. BAERC conducted a laboratory performance test to determine the planting parts' desired functionality. Continuous monitoring and timing of every action, as well as time losses for turning at headland and adjustment, were part of the inquiry into the planter's effective field capacity and field efficiency. Using the following Eqns. (

11), (

12) and (

13), the effective field capacity and field efficiency were determined

| [5] | Bamgboye, A. I. and Mofolasayo, S. A. Performance evaluation of a two-row okra planter. Agricultural Engineering International: CIGR Journal, 8, 2006, 1-10. |

[5]

. Therefore, considering the theoretical field capacity, effective field capacity, and field efficiency of the planting machine, it was determined that they were 0.31 ha/hr, 0.81 ha/hr, and 0.25 ha/hr, respectively.

(11)

(12)

(iii). Wheel Skid Determination

Wheel skid will happen during regular operation if the machine is land wheel powered. When the wheels skid, the machine's forward motion will increase for a specific number of drive wheel revolutions. The machine was pushed or towed slowly out of operation, and the distance traveled during five wheel revolutions was noted (B). During field work, the distance for 5 wheel revolutions was again be measured (A). As far as the wheel of the planter was made of the ridged having tractive performance there was no more visible skidding was determined, if the soil is muddy sinking problem was investigated at field tractive performance test. The following formula will be used to determine the percentage wheel skid

| [21] | Testing and evaluation of agricultural machinery and equipment - Principles and practices, 1994. |

[21]

.

(14)

7. Variables and Data Collection

Care was taken during the test to make sure the seed exits didn't get obstructed and that the metering mechanism was operating as intended. Blockage of the seed and fertilizer delivery hoses were occurred due to improper farm land preparation, so that frequent check and adjustment was made at any time. At the end of the test run, the hoppers are emptied and the remaining seed will be weighed. The following measurements was made:

1) Number of passes

2) Number of rows per pass

3) Row spacing

4) Forward speed

5) Whenever appropriate, a wheel skid

6) The amount of time spent turning, maintaining, and adjusting

7) Total hours spent in operation

Additionally the following qualitative observations were investigated at field and laboratory performance test in relation farm land conditions:

1) Blockage of working parts, ease of handling, and ease of adjustment

2) Easy to manage and tedious

Hence at some stage in the overall performance assessment the machine effortless of handling, changes of seed and fertilizer was once made from lever effortlessly and blockage of the delivery chutes additionally without problems identified, beside to this controlling of ahead and gasoline had been made from lever arm provided, drudgery used to be investigated due to vibration.

8. Result and Discussion

The Bako Agricultural Engineering Research Center designed, built, tested, and assessed the performance of a prototype self-propelled air assisted engine driven teff row planting equipment. The planting machine is made up of a traction wheel, several power transmission systems, an air diffusion chamber, and mechanisms for measuring fertilizer and seeds. Field efficiency, effective field capacity, consistency of seed delivery inside and between rows, regularity of row line spacing, and other factors were used to evaluate the self-propelled planting machine's performance. To ascertain the degree and scope of the variables' impact on the machine's performance, the data gathered during the performance test following seed germination was subjected to an ANOVA.

8.1. Laboratory and Field Performance Evaluation Results

The planting machine's effective field capacity, theoretical field capacity, and field efficiency were determined to be 0.25 ha/hr, 0.31 ha/hr, and 0.81 ha/hr, respectively, during the performance evaluation. As it was observed from ANOVA table the significant difference in application uniformity within row was determine at varied numbers of sample data taken. The largest plant population was observed replication 5 and the smallest observation was recorded at replication 3 which was 141.3 and 103.5 respectively. The uniformity application row to didn’t show statically significant difference, even if the was significant note on qualitative and there was no significant different on application uniformity across rows randomly recorded samples. There from the

table 1 below it was noted that there was no variation in seed distribution uniformity when distribution of each row were compared.

Table 1. Plant population determined per each and across rows.

Rep | Application uniformity within row | Application uniformity across rows randomly |

| Row | Row |

1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 |

1 | 123.0 | 133.4 | 132.1 | 130.9 | 97.9 | 129.0 | 130.9 | 129.9 | 123.5 |

2 | 135.6 | |

3 | 103.5 |

4 | 114.4 |

5 | 141.3 |

After the emergence of the seeding the number of seedling were counted to determine plant population to investigate seed distribution uniformity of the metering mechanism stated in above

table 1. As it can be noted from

table 2 below row space and row line uniformity were measured, the collected data was subjected ANOVA, and the following result was obtained. During the seeding the row to distance assumed to be 20cm, but due to vibration distribution it increased to as it was shown from the table. The highest mean of row space was recorded at row three which was 27.8 cm and the highest row line uniformity was observed at row 1 as revealed in the following

table 2.

Table 2. Mean value of row space and row line uniformity.

Row | Row space | Row line uniformity |

Replications |

| 1 | 2 | 3 | 4 | 5 |

1 | 27.4 | 26.7 | 27.5 | 27.5 | 27.7 | 27.9 | 11.6 |

2 | 27.4 | | | | | | 11.3 |

3 | 27.8 | | | | | | 11.3 |

4 | 27.3 | | | | ` | | 11.5 |

Some qualitative like visual observation was made metering mechanisms and has better distribution when the machine is moving, this is of that the vibration used as agitation and the air bellowing the seed out. Walking less the human speed might result in high plant population that is when walking speed is less than 1.25m/s. 81% of the mean values of the acquired field efficiencies were found to equal the field efficiency. As it falls within the range of values obtained for planting operations from the work of

| [5] | Bamgboye, A. I. and Mofolasayo, S. A. Performance evaluation of a two-row okra planter. Agricultural Engineering International: CIGR Journal, 8, 2006, 1-10. |

[5]

, this demonstrates a good and satisfactory performance. Additionally, the field evaluation yielded an effective field capacity of 0.25 ha/hr. When compared to comparable outcomes for a motorized seed planter published in certain publications, the machine's performance output is satisfactory

| [19] | Oduma, O., Ede, J. C and Igwe, J. E. Development and performance evaluation of a manually operated Cowpea precision planter. International journal of engineering and technology, 4(12), 2014, 693-699. |

[19]

. A manual planter created by was achieved 76.3% field efficiency and 0.03 ha/hr field capacity.

8.2. Conclusion

An engine-powered, self-propelled teff row planter with a novel metering mechanism design concept was created. In order to determine factors like field efficiency, field capacity, time of operations, and traction performance, it was assessed in both the lab and the field. This is to observe and determine the planter's performance and functionality. 81% field efficiency and 0.25 ha/hr field capacity were noted during the planter's field performance. Poor seed placement, inefficient spacing, and significant farm labor were among the issues that the planter was able to resolve by disseminating teff seed planting with a high seed rate in conventional planting and manual techniques of seed planting.

8.3. Recommendation

For more than one decade several private and government institution have made unreserved contribution to produce teff row planting machine. Most of the findings have reported that majority of the planter developed were animal drawn which is difficult to control with animals behavior and teff farm land moisture conditions. Therefore BAERC has paced one step forward in developing self-propelled five row teff and fertilizer planting which can be operated in any soil conditions. The machine was evaluated on vertisoil and acceptable performance parameters were investigated with the following recommendations:-

1) The machine was evaluated on vertisoil only and must be sought for light soil because the parameters under estimated for this types soil (light soil).

2) The machine requires ballast at front side to have enough tractive power.

3) The contact length of the traction wheel must be decreased because it causes huge load in muddy farm land.

4) The operator have to control from the seating and have to ride on the planter to control the metering, furrow opener.

5) Given its current state, the machine was strongly advised to end users.

6) The machine can be utilized for various crops by modifying the metering mechanism and for ploughing in light soil, apart from its primary function of planting teff.

Abbreviations

ANOVA | Analysis of Variance |

ATA | Agricultural Transformation Agency |

BAERC | Bako Agricultural Engineering Research Center |

Vt | Terminal Velocity |

Wb | Wett Based |

Conflicts of Interest

The authors declare no conflicts of interest.

References

| [1] |

Abdalla, A. N. O. 2007. Comparison of two row planting machine performance as affected by forward speed under two soil condition. M.SC. Thesis University of Khartoum.

|

| [2] |

Abraham R, Dechassa N, Assefa K. Evaluation of seed rates and sowing methods on growth, yield and yield attributes of tef [Eragrostis tef (Zucc.) Trotter] in Ada District, East Shewa, Ethiopia. Am Eur J Agric Environ Sci. 2018; 18(1): 34–49.

|

| [3] |

Abduljelil, M., 2010. Investigation into tef grain, straw and chaff mixture separation and cleaning. Unpublished Master’s. Thesis). Adama University, Adama, Ethiopia.

|

| [4] |

ASME. 1995. Design of Transmission Shafting. American Society of Mechanical Engineering, New York, NY USA.

|

| [5] |

Bamgboye, A. I. and Mofolasayo, S. A. Performance evaluation of a two-row okra planter. Agricultural Engineering International: CIGR Journal, 8, 2006, 1-10.

|

| [6] |

Behailu Getu. 2014. Assessment of Factors Affecting Farmers’ Adoption level of Row Planting Technology and Yield Improvement on the Production of Eragrostis Teff [ZUCC.], Addis Ababa University.

|

| [7] |

Bekabil fufa, Befkadu Behute. 2011. Rupert Simon, and Tareke Berhe, Strengthening the tef value chain in Ethiopia, Ethiopia agricultural transformation agency.

|

| [8] |

Debelo, Aberra, 1992. Germination, yield, and yield components of tef (Eragrostis tef (Zucc) Trotter) as affected by environment, tillage and weed control practices. Oklahoma State University.

|

| [9] |

Ethiopian agricultural transformation Agency (ATA) in 2013 report.

|

| [10] |

Eugene, A. A. and Theodore, B. (1986): Standard Handbook for Mechanical Engineering. McGraw Hill Book Company, P. 8-57.

|

| [11] |

Fadele, O. K. and Aremu, A. K., Effects of Seed Condition, Operation and Design Parameters On Out-Turn Of Moringa Kernel.

|

| [12] |

Gumble, L. O., & Maina, C. (1990). Friction coefficient of cereal seeds on various surfaces. Agricultural Mechanization in Asia, Africa and Latin America, 21(4), 61–64.

|

| [13] |

Karayel, D., and A. Özmerzi. "Evaluation of three depth-control components on seed placement accuracy and emergence for a precision planter." Applied Engineering in Agriculture 24.3 (2008): 271-276.

|

| [14] |

Kassaye, Wubante Negash Ahadu Menzir Mulatu. "Effect of Row Spacing on Yield and Yield Components of Teff [Eragrostis tef (Zucc.) Trotter] Varieties in Gonji Kolela District, North Western Ethiopia".

|

| [15] |

Kyada, A. R and Patel, D. B. 2014. Design and Development of a Manually Operated Seed Planter. 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014) December 12th–14th, 2014, IIT Guwahati, Assam, India.

|

| [16] |

Khrmi, R. S & Gupta, J. K (2004), Theory of Machines, Eurasia publishing housing, New Delhi.

|

| [17] |

Mohsenin, N. N., Jindal, V. K. and Manor, A. N., 1978. Mechanics of impact of a falling fruit on a cushioned surface. Transactions of the ASAE, 21(3), pp. 594-0600.

|

| [18] |

Mysara, A. M, Abdalla, N. O. K., Abbas, E. R. and Husam, A. B. Y. 2017. Performance evaluation of two planters make as affected by forward speeds. Journal of Agricultural Science and Practice. 2, 16 – 22.

|

| [19] |

Oduma, O., Ede, J. C and Igwe, J. E. Development and performance evaluation of a manually operated Cowpea precision planter. International journal of engineering and technology, 4(12), 2014, 693-699.

|

| [20] |

Soyoye, B. O., Ademosun, O. C. and Agbetoye, L. A. S. 2018. Determination of some physical and mechanical properties of soybean and maize in relation to planter design. Agricultural Engineering International: CIGR Journal, 20(1), 81–89.

|

| [21] |

Testing and evaluation of agricultural machinery and equipment - Principles and practices, 1994.

|

| [22] |

Zewdu. and Solomo. 2007. Moisture dependant physical properties of Teff seed, bio-systems engineering. 96(1): 59-63.

|

Cite This Article

-

APA Style

Workesa, M., Lammessa, S. (2025). Development and Performance Evaluation of an Engine Driven Air Assisted Teff Planter. Industrial Engineering, 9(2), 48-59. https://doi.org/10.11648/j.ie.20250902.13

Copy

|

Copy

|

Download

Download

ACS Style

Workesa, M.; Lammessa, S. Development and Performance Evaluation of an Engine Driven Air Assisted Teff Planter. Ind. Eng. 2025, 9(2), 48-59. doi: 10.11648/j.ie.20250902.13

Copy

|

Copy

|

Download

Download

AMA Style

Workesa M, Lammessa S. Development and Performance Evaluation of an Engine Driven Air Assisted Teff Planter. Ind Eng. 2025;9(2):48-59. doi: 10.11648/j.ie.20250902.13

Copy

|

Copy

|

Download

Download

-

@article{10.11648/j.ie.20250902.13,

author = {Merga Workesa and Solomon Lammessa},

title = {Development and Performance Evaluation of an Engine Driven Air Assisted Teff Planter

},

journal = {Industrial Engineering},

volume = {9},

number = {2},

pages = {48-59},

doi = {10.11648/j.ie.20250902.13},

url = {https://doi.org/10.11648/j.ie.20250902.13},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.ie.20250902.13},

abstract = {Teff is a staple of Ethiopian culture and national identity and is very nutrient-dense. Ethiopia and its farmers now have more economic opportunities as a result. The process of planting involves putting seeds in the ground for optimal germination. It is among the most significant cultural customs related to the production of crops. At present it has little development in teff row seeder in Ethiopia. However, their field evaluations showed that, none of the developed planters has been functioned effectively, in way of the desired functional requirement, especially in all soil types as well as weather conditions of the country. So many research institutes and private sectors have been developed different types of teff row planting device which seed from single to many rows, animal drawn and operated manually. This work focused on the creation and performance evaluation of an inexpensive self-propelled five rows air seeder teff row planter in order to overcome the need for human labor for sowing, which leads to delayed operation, low yield, and high production costs. The developed machine consists of different major component parts like seed and fertilizer hoppers, driving wheel, air diffuser, controlling mechanism, seed and fertilizer delivery chute and the like. The planting machine's effective field capacity, theoretical field capacity, and field efficiency were determined to be 0.25 ha/hr, 0.31 ha/hr, and 0.81 ha/hr, respectively, during the performance evaluation. The largest plant population was observed replication 5 and the smallest observation was recorded at replication 3 which was 141.3 and 103.5 respectively.

},

year = {2025}

}

Copy

|

Copy

|

Download

Download

-

TY - JOUR

T1 - Development and Performance Evaluation of an Engine Driven Air Assisted Teff Planter

AU - Merga Workesa

AU - Solomon Lammessa

Y1 - 2025/10/17

PY - 2025

N1 - https://doi.org/10.11648/j.ie.20250902.13

DO - 10.11648/j.ie.20250902.13

T2 - Industrial Engineering

JF - Industrial Engineering

JO - Industrial Engineering

SP - 48

EP - 59

PB - Science Publishing Group

SN - 2640-1118

UR - https://doi.org/10.11648/j.ie.20250902.13

AB - Teff is a staple of Ethiopian culture and national identity and is very nutrient-dense. Ethiopia and its farmers now have more economic opportunities as a result. The process of planting involves putting seeds in the ground for optimal germination. It is among the most significant cultural customs related to the production of crops. At present it has little development in teff row seeder in Ethiopia. However, their field evaluations showed that, none of the developed planters has been functioned effectively, in way of the desired functional requirement, especially in all soil types as well as weather conditions of the country. So many research institutes and private sectors have been developed different types of teff row planting device which seed from single to many rows, animal drawn and operated manually. This work focused on the creation and performance evaluation of an inexpensive self-propelled five rows air seeder teff row planter in order to overcome the need for human labor for sowing, which leads to delayed operation, low yield, and high production costs. The developed machine consists of different major component parts like seed and fertilizer hoppers, driving wheel, air diffuser, controlling mechanism, seed and fertilizer delivery chute and the like. The planting machine's effective field capacity, theoretical field capacity, and field efficiency were determined to be 0.25 ha/hr, 0.31 ha/hr, and 0.81 ha/hr, respectively, during the performance evaluation. The largest plant population was observed replication 5 and the smallest observation was recorded at replication 3 which was 141.3 and 103.5 respectively.

VL - 9

IS - 2

ER -

Copy

|

Copy

|

Download

Download

(1)

(1)  (2)

(2)  (3)

(3)  (4)

(4)  (5)

(5)  (6)

(6)  (7)

(7)  (8)

(8)

= coefficient of friction between belt and pulley;

= coefficient of friction between belt and pulley;